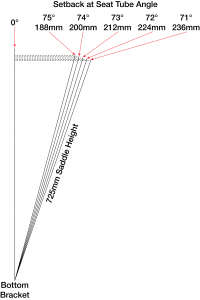

After building up the All-City Electric Queen and riding it a handful of times, it just didn’t feel… right. Standing and handling the bike was fine, but seated pedaling — especially when climbing or just after sitting back down — felt quite off. Turns out the problem was the 71° seat tube angle on the frame coupled with my shorter femurs; I simply can’t get the saddle far enough forward on one of these frames.

Unfortunately, the only good solution was to get a different frame. The Salsa Timberjack was my original choice for this hard tail trail bike build, but I got excited by the idea of a steel bike, loved the paint on the Electric Queen, and glossed over the seat tube angle. By the time I realized I needed a new frame the stand-alone black frames were no longer available. Fortunately, over at the excellent Sports Rack Marquette, Evan had some new frames from complete bikes available, and I was able to get a beautiful gloss teal frame from a 2019 Timberjack Deore 27.5+ from them.

Besides matching my wants geometry-wise, the frame is a great choice because all parts except for the headset swapped over, and the frame came with a headset. While the stock Cane Creek 10 is a lower end part, which lacks sealing on the top bearing cover and has a plastic compression rings and crown races and black oxide bearings, it works and will be fine for a while. The fork was already fitted with a higher end matching crown race, and I have a Cane Creek Hellbender 70 headset ready swap in once the bearings and compression ring start to go.

One downside to the Timberjack vs. Electric Queen is that I’ll no longer have a rigid fork for the bike, but if I really want one the Firestarter 110 Deluxe is a perfect match. The top tube on this bike is also a little bit tall, as it’s also designed for bikepacking and fitting a top tube bag, but it’s plenty comfortable to ride and I love all the bottle cage options.

To round out the build and get the colors nice I ordered some new fork decals from Slik Graphics. Unfortunately, I screwed up and ordered the decals for the Factory-series forks, so while it looks good, I technically have the wrong upper logo on the fork lowers. I’ve since ordered another set with the proper Performance decals for the upper, and am waiting for them to arrive. Since this order was placed Slik became involved in a dispute with Fox, so I’m hoping to receive the updated decals. Even if they don’t arrive, at least the colors are right on the fork. I could even remove the upper decals and have it still look good.

When finishing up the build I ran into a significant problem with the brakes: squealing and vibration. Due to part availability I’d purchased the calipers and levers as a non-retail / meant-for-complete-bikes / likely grey market set from a well-known eBay seller, ronde-cycling. I was never able to get them bedded in properly, and after a few rides they began squealing horridly and shuddering under hard braking. This seller offers different pads options with the brakes, and I began to suspect they handle the pads with each brake set sale, did so poorly, and contaminated the pads before they got to me.

I tried the normal recommendations of cleaning everything, sanding the pads and rotors, and even baking the pads in the oven, but on each bed-in procedure they’d begin squealing again. Resolution a set of new J04C pads and a bed-in and now the brakes are working great. At ~$50 for a new set of pads this really added to the cost of the brakes, but at least they are now working.

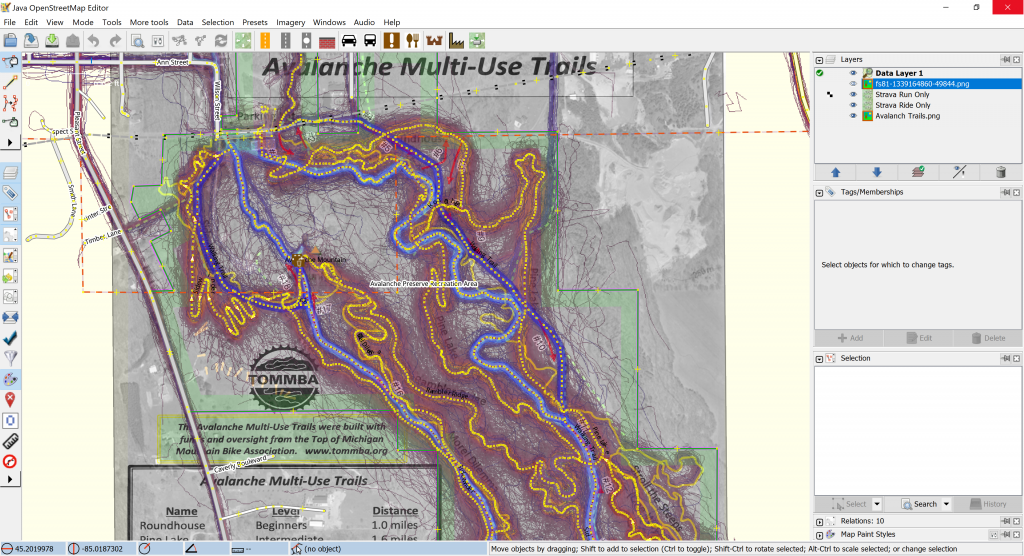

Final build, with water bottle cages, pedals, and computer came out to right around 27 pounds. And, it fits! Since building it I’ve put over 180 miles and nearly 16 hours on the bike, haven’t touched the geometry, and I’m really happy with the result. It’s exactly what I wanted; a high quality hard tail trail bike.

Full details below:

Frame: Salsa Timberjack (Large, Teal, 2019)

Fork: Fox 34 Step-Cast (Performance, FIT4 damper, Black Upper Tube Finish, 120mm, 51mm offset, 15QR)

Fork Decals: Slik Graphics Fox 34 Step-Cast Factory Style Decal Kit / Fox 34 Step Cast Performance Elite Decal Kit (Color 1: Medium Grey, Color 2: Dark Grey, Finish: Matte)

Headset: Cane Creek 10 (Black, ZS44/ZS56)

Crankset: SRAM X1 1400 GXP

Bottom Bracket: SRAM GXP (Black)

Chainring: SRAM X-SYNC 2 (32t, steel, Direct Mount, 3mm / Boost)

Derailleur: SRAM GX Eagle

Shifter: SRAM GX Eagle

Shift Cables / Housing: Shimano Bulk

Cassette: SRAM XG-1275

Brakes: Shimano SLX M7100 (Levers: BL-M7100, Calipers: BR-7100)

Brake Pads: Shimano J04C (Finned, Metal)

Front Rotor: SM-RT86-L (203mm)

Rear Rotor: SM-RT86-M (180mm)

Front Brake Adapter: SM-MA-F203P/P (160mm Post to 203mm Post)

Rear Brake Adapter: Shimano SM-MA-R180P/S (IS to 180mm Post)

Stem: Salsa Guide (+6°, 60mm)

Bar: Salsa Salt Flat (750mm)

Wheels: Industry Nine Trail S Hydra 28H (29″)†

Tires: Maxxis Rekon (29 x 2.4″, 3C/EXO/TR)

Seatpost: Fox Transfer Performance Elite (2020, Black, 125mm, 30.9mm, Internal)

Dropper Lever: Wolf Tooth ReMote Light Action (Black, 22.2mm Clamp)

Seatpost Collar: Salsa Lip-Lock (Black, 35.0 mm)

Saddle: Specialized Power Expert (143mm)

Pedals: Crank Brothers Eggbeater 3 (Green, from Blackborow)

Grips: ESI Extra Chunky (Black)

Bottle Cages: Specialized Zee Cage II (Black Gloss, 1x Left, 2x Right)

Computer: Garmin Edge 530, Garmin Speed and Cadence Sensors (v1), Best Tek Garmin Stem Mount

Bell: Mirracycle Original Incredibell (Black)

Derailleur Hanger: QBP FS1373

Frame Protection Tape: 3M 2228, McMaster-Carr UHMW PE

Cable Rattle Prevention: Frost King EPDM Weatherseal (V25A, slipped over dropper housing)